|

Deutsch

|

Deutsch

WL1+ calculates load, stresses and critical speeds of shafts, safety according to DIN743, as well as the roller bearing life expectancy according to DIN.

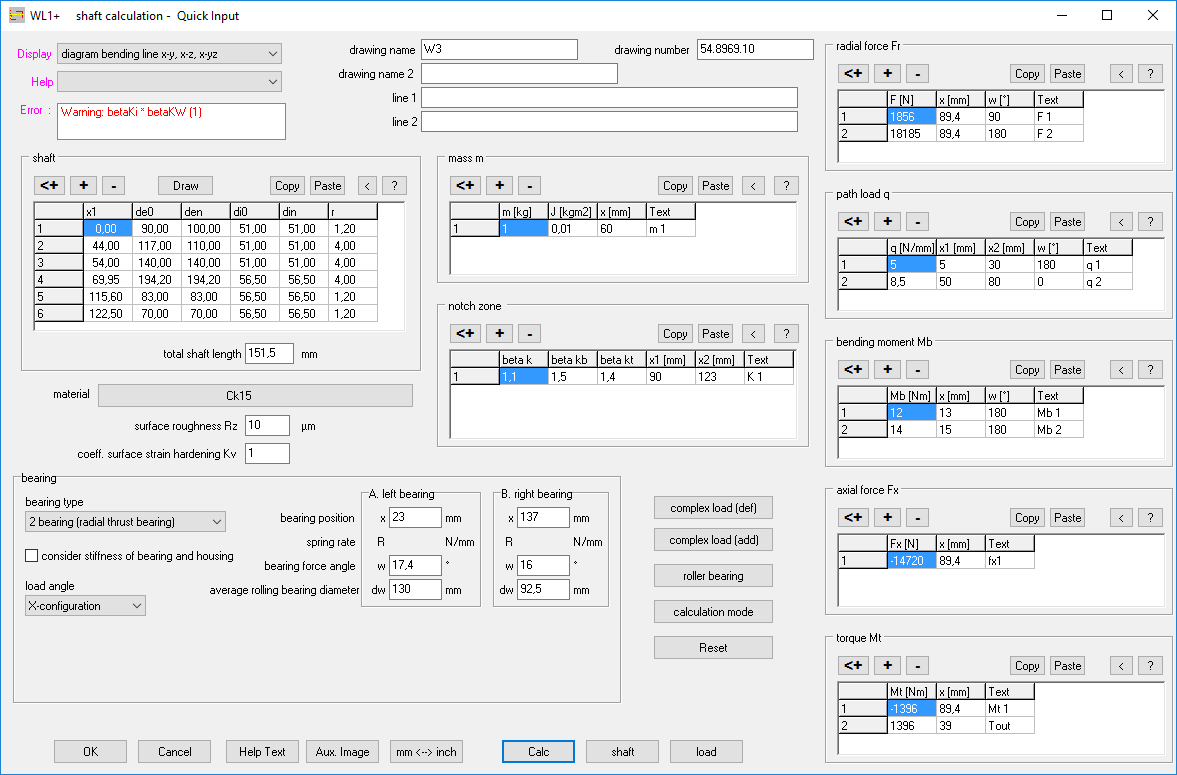

Quick input provides input of all dimensions, bedding, material, forces, path loads, bending moments and torque altogether in one dialogue window. Click "Calc" button for shaft calculation and select at "Display" result as graphic, tables, drawing, diagram.

The shaft can have up to 100 cylindrical or conical shaft segments. Up to 50 individual forces, path loads, bending moments, torques and axial forces can be assigned. WL1+ converts stress from gears into path loads, axial forces, torques and bending moments. The easiest input method is, however, to import the gear forces calculated by our Gear Program ZAR1+.

Stress concentration effectThe increased stress at shaft transions is automatically taken into account when you enter surface values, sensitivity factors and transition radius. Zones with increased stress concentration effect (e.g. from sliding key grooves) can be taken into account by entering beta k, beta kb and beta kt when calculating torsion and bending stress.

WL1+ calculates statically determinate supported shafts with fixed and loose bearings, fixed clamping and radial thrust bearings, each bearing absorbs axial forces in only one direction. In addition, statically undeterminate supported shafts with 3, 4 or 5 bearings can also be calculated.

Material DatabaseThe most important steels are included in the data base provided. Further steels and non-ferrous metals are made available by accessing the WST1 material database.

The critical speeds for flexural and torsional vibration are calculated from the shaft's inherent mass and other fitted masses (e.g. rotor body, ring gear, belt pulley) according to the Kull & Dunkerley method.

Reference StressIt is possible to calculate reference stress from the bending, tension and shearing stresses according to the maximum stress theory, maximum shear theory or maximum distortion energy theory.

The WL1+ package includes database files in XBase format with 600 deep-groove ball bearings, 100 self-aligning ball bearings, 70 needle bushes, 170 needle bearings, 500 cylindrical roller bearings, 300 tapered roller bearings, 360 self-aligning roller bearings, 100 angular contact ball bearings and 180 needle roller cages per SKF and INA documentation. The database can be appended and modified as required.

Charts

Torque, bending moment, bending angle, deflection line, bending stress, shearing stress and reference stress curves provide important information. You can print the charts out, save them to DXF files or incorporate them into your documentation via the clipboard.

On the basis of the calculated values for reaction force and basic load ratings, you can choose the appropriate roller bearing from the WL1+ database. WL1+ calculates life expectancy according to ISO 281.

PrintoutThe printout shows the extreme values for bending moment, deflection line, bending stress, shearing stress and reference stress along with shaft weight, mass moment of inertia, centre of gravity, support forces, bending angle on the bearing surface, bearing life expectancy, critical speeds, material values and all input data.

CAD InterfaceAfter WL1+ has calculated the shaft, you can export the DXF or IGES generated files with the scale drawing of the shaft complete with rolling bearings directly to your CAD system.

HEXAGON Help SystemFor explanation of the input data you can display help text and pictures, as is necessary. WL1+ automatically provides error messages for input errors and when value limits are exceeded. For each error message you can display more detailed information and suggestions for remedial action.

GuaranteeHEXAGON gives a 24-month guarantee on full functionality of the software. We provide support by email and hotline. Our software is continously improved and updated. Customers will be informed regularly of updates and new editions.