ZAR8 - Software for Ravigneaux Gears

A Ravigneaux gear contains two planetary gear stages: one (minus) planetary gear set and one plus planetary gear set with planet gear pairs instead of planet gears. Carrier as well as ring gear of both planetary gear sets are connected or common. And planet wheel of the minus planetary set is used as outer planet wheel of the plus planetary gear set.

Five gear wheels in two planetary gear sets: Si (small sun wheel), Pi (inner planet wheel), Pe (outer planet wheel), H (hollow wheel), Se (large sun wheel) are calculated by ZAR8 in one pass.

In pre-dimension, you can enter transmission ratio of first gear and fourth gear. The transmission of the other gears 2, 3 and R are directly calculated and displayed, also the gear step between gear 1,2,3,4. Transmission ratio i0i of plus planetary gear set is transmission ratio of the 1st gear, and transmission ratio of the minus planetary gear set i0e is transmission ratio of the rear gear.

Next enter power or input torque and input speed. You can define number of teeth of the ring gear zH, and ZAR8 calculates dimensions of all gear wheels under consideration of assembly conditions for planetary gear sets.

In the next input window you can modify dimensions such as profile shift coefficients, tooth tip reduction, face width of the gear wheels.

Four connector shafts Si, C, H, Se can be defined as driving (in), driven (out), control or idle. By means of the buttons 1,2,3,4,R you can shift the standard gears of the Ravigneaux gear.

In an animation you can rotate the gear wheels of the Ravigneaux gear set on the computer screen.

To calculate load bearing capacity for each of the five gear wheels and four tooth contacts (Si-Pi, Pi-Pe, Pe-H, Se-Pe), select gear materials from integrated database and input additional data for strength calculation according to ISO 6336 or DIN 3990.

ZAR8 is available now for 1950 EUR.

ZAR7 Software for Plus Planetary Gears (double-planet gears)

A Ravigneaux gear is composed of one simple (minus) planetary gear stage and one plus planetary gear set. A minus planetary gear set can be calculated by means of ZAR5. For calculation of a plus planetary gear set, we have made a new software ZAR7. The carrier of a plus planetary gear carries planet gear pairs instead of single planets as in ZAR5. Planet wheel pairs may be on one axis to the center of the sun gear, but usually are offset mounted. This allows larger number of teeth and free definable profile shift coefficients. For number of teeth of ring gear (zH) and sun wheel (zS), assembly condition for plus planetary gears must be considered:

(|zH| - zS) / q = f

"f" must be integer. "q" is the number of planet pairs.

Dimensions and load capacity of the four gear wheels S (sun), Pi (inner planet), Pe (outer planet) and H (hollow gear) calculates ZAR7 in one pass. Additionally, you can select roller bearings for inner planets and outer planets and calculate in ZAR7.

ZAR7 is available now for 1380 EUR.

Planetary Gear Package

Our new planetary gear package contains the programs for design and calculation of planetary gears ZAR5, ZAR7, ZAR8, GR1, and also ZAR1+ for a price of 3600 Euros. If upgrade from ZAR1+ or ZAR5 or spur gear package, old licenses are credited 75%.

GR1 - Gear Construction Kit Software

By means of GR1 you can "build" multistage gears composed of simple gear pairs, planetary gear sets, Ravigneaux gear sets, Simpson gear sets and plus planetary gear sets. For each gear stage element you can define if it is driving (in), driven (out), blocked or idle. For driving elements (i9) you can enter input speed or select a predecessor gear element.

GR1 calculates speed and transmission ratio of all gear elements.

GR1 does not calculate power, torque nor dimensions.

GR1 is available now for 185 Euros.

FED1+,2+,3+,5,6,7,8: Hot-Coiled Springs: 2E6 Load Cycles

Cold-coiled springs are fatigue strength safe if enduring more than ten million load cycles. In the spring calculation software, this was treated equal for hot-coiled springs until now. But Goodman diagrams in EN 13906-1 for hot-coiled springs are drawn for 2E6 load cycles (fatigue strength safe) and for 1E5 load cycles. The EN 13906 Goodman diagram for hot-coiled springs shows curves for bar diameters of d=10mm, 15mm, 25mm, 35mm and 50mm. These diagrams with fatigue strength safety for 2E6 instead of 1E7 load cycles (for hot-coiled springs only) are used now in our software for compression springs, extension springs, torsion springs and torsion bars. However, at "Edit->Calculation Method" you can configure the calculation as used until now with fatigue strength safety at 10 million load cycles for all spring materials.

Goodman diagrams for hot-coiled springs are valid for spring materials to EN10089 with ground or shaved surface. At "Edit->Production" you must set "hot-coiled, steel with reworked surface" and at "Edit->Material->Surface" "ground" or "shaved". For hot-rolled spring steel with drawn or rolled surface is no Goodman diagram available. Instead of 3 curves for 10 million, 1 million and 100,000 load cycles, new Goodman diagram for hot-rolled springs shows only 2 curves: for 2 million cycles and 100,000 cycles.

FED1+, 2+,3+,5, FED6, 7,9: Spring drawings in command line mode

Drawings created in command line mode (i.e. "wfed1 test.fed /CAD1:27") were drawings of the unloaded spring with spring length L0 until now. This has been changed, spring drawings are created in the defined spring length now. This enables you to automate spring drawings as DXF or IGES file in various spring lengths.

FED1+: Quick Input Window: Assembly length L for spring drawings

If you selected spring drawings (front view, section drawing, 3D), you can input assembly length L next to "Display" field now.

In FED1+, indices for drawings and diagrams used in command line mode are now equal with indices in Quick Input window, this begins with index 1 = "Quick 1" until Index 35 "stress Rm-d Quick". Index 25, 26, 27 for spring drawings (view, section, 3D centerline). Example command line: "wfed1 actual.fed /cad1:25"

FED4: SigmaOM

Bending stress SigmaOM of the disk spring is mainly used to calculate static stressed disk springs. SigmaOM has been added to stress diagrams and printout.

FED4: Load cycles for disk spring materials according to DIN 2093

In FED4 you can decide to use material according to DIN 2093 or from material database. Calculation of load cycles has been added to disk springs with material data to DIN 2093.

GEO4, ZAR4: New Input Windows Sinus-Linear, Polygon, Eccentric

New input windows were created for cam geometry in GEO4 and for pitch curve of nonlinear gear in ZAR4 for sine-linear, polygon and eccentric element geometry.

ZAR1+, ZAR5: New Dialogue Window for Strength Calculation Data

Input data for strength calculation to ISO 6336 and DIN 3990 have been integrated into one common dialogue window.

ZAR1+, ZARXP, ZAR1W, ZAR5: Drawing Options and Ring Gear with Bore Holes

Same as known from WN2, at "CAD->Gear Wheel" and "STL->Gear Wheel" you first get a dialogue window with settings. New for ring gears is the possibility to define a pitch circle with bore holes. This is useful if you produce ring gears directly with 3D printer.

SR1/SR1+ : Tightening Torque

Instead of min/max tightening torque MA,max and MA,min, or nueRp and alphaA, you have a new alternative to input average tightening torque with tolerance in % instead.

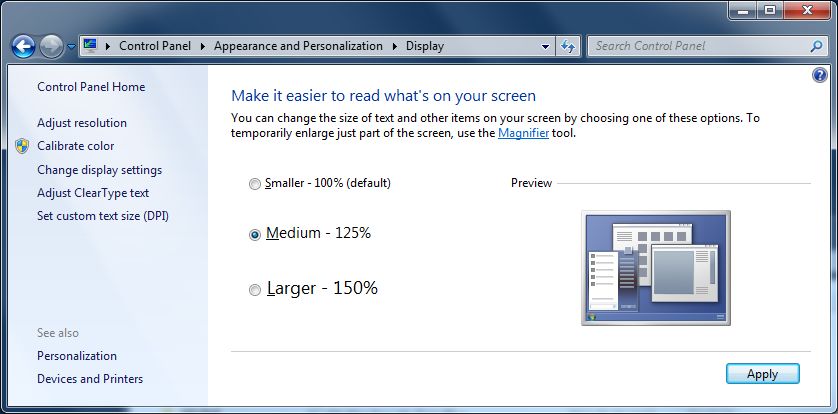

Modify Dialogue Window Size and Dialogue Element Size (Text Size)

If text and input fields are too small (i.e. notebook with high graphic resolution but small display) you can modify dialogue window size and dialogue element size at "File->Settings->Graphics". Also in Control Panel of Windows you can modify size of text and dialogue elements. These Windows settings differ in Windows 10, Windows 8, Windows 7.

If you make changes in the Windows settings, you maybe next have to adapt the new settings in the HEXAGON programs. Or set "Auto" instead of "Input" to adapt Windows settings automatically.

We improved handling with enlarged dialogue windows, input tables were not enlarged in previous versions. Also we fixed a bug at enlarging database windows. If you configure dialogue element size, save new configuration, then close and restart program to set new text size also for database windows. Anyway, if you plan to use HEXAGON software with enlarged dialogue elements and dialogue windows, we recommend first to update your programs to the latest version.

FED17 - New Software for Magazine Springs

Especially for compression springs with rectangular, oval or elliptic coil shape we can provide a new software in short.